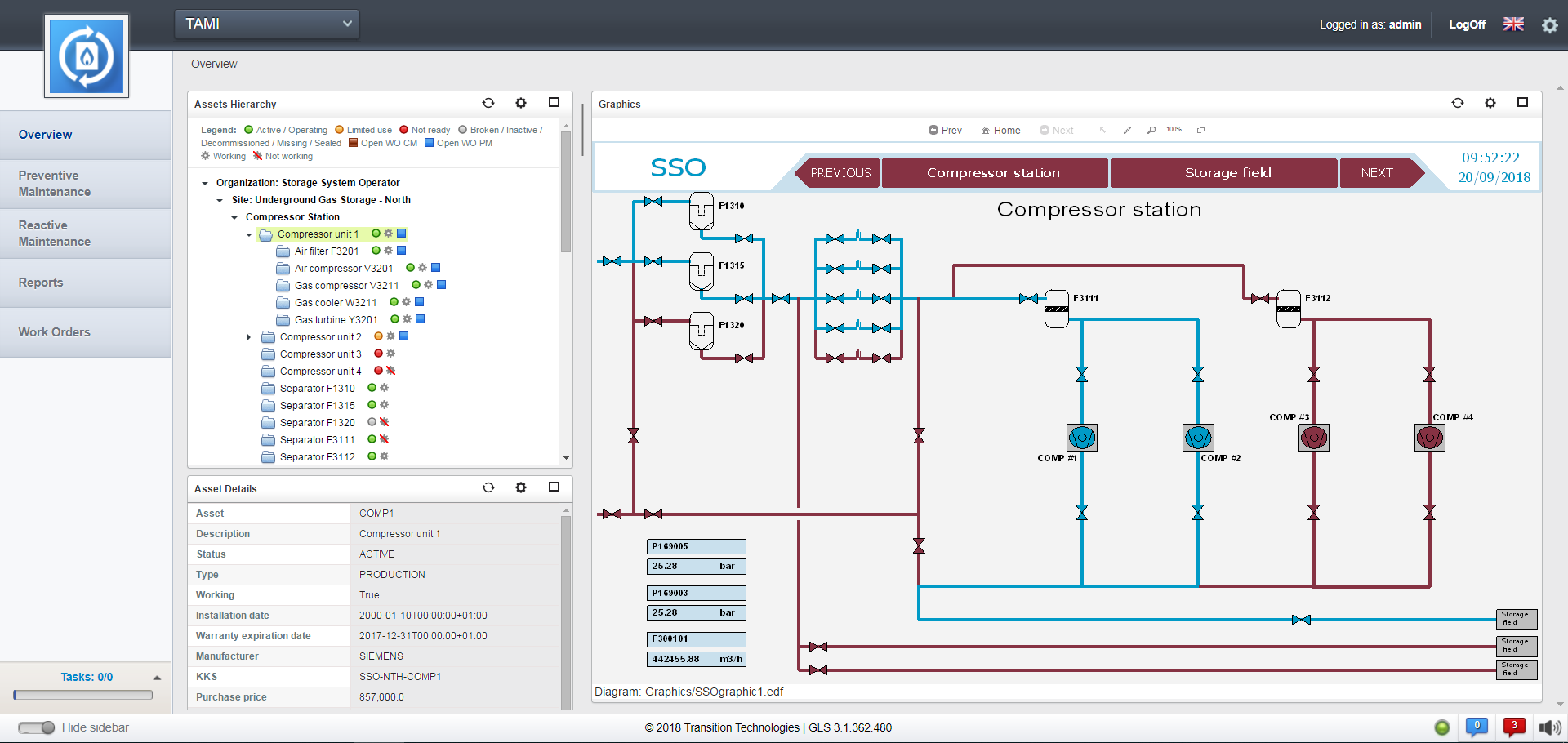

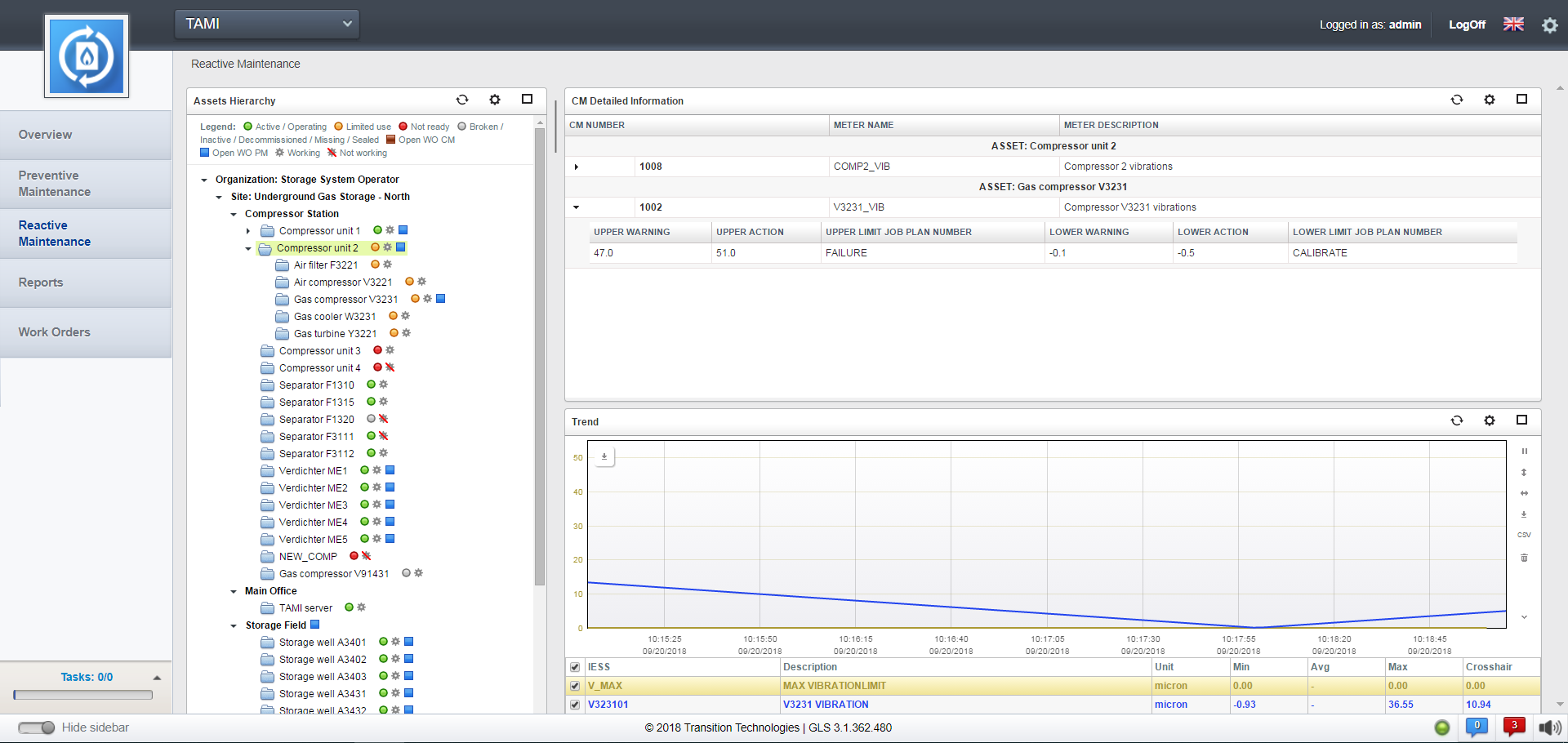

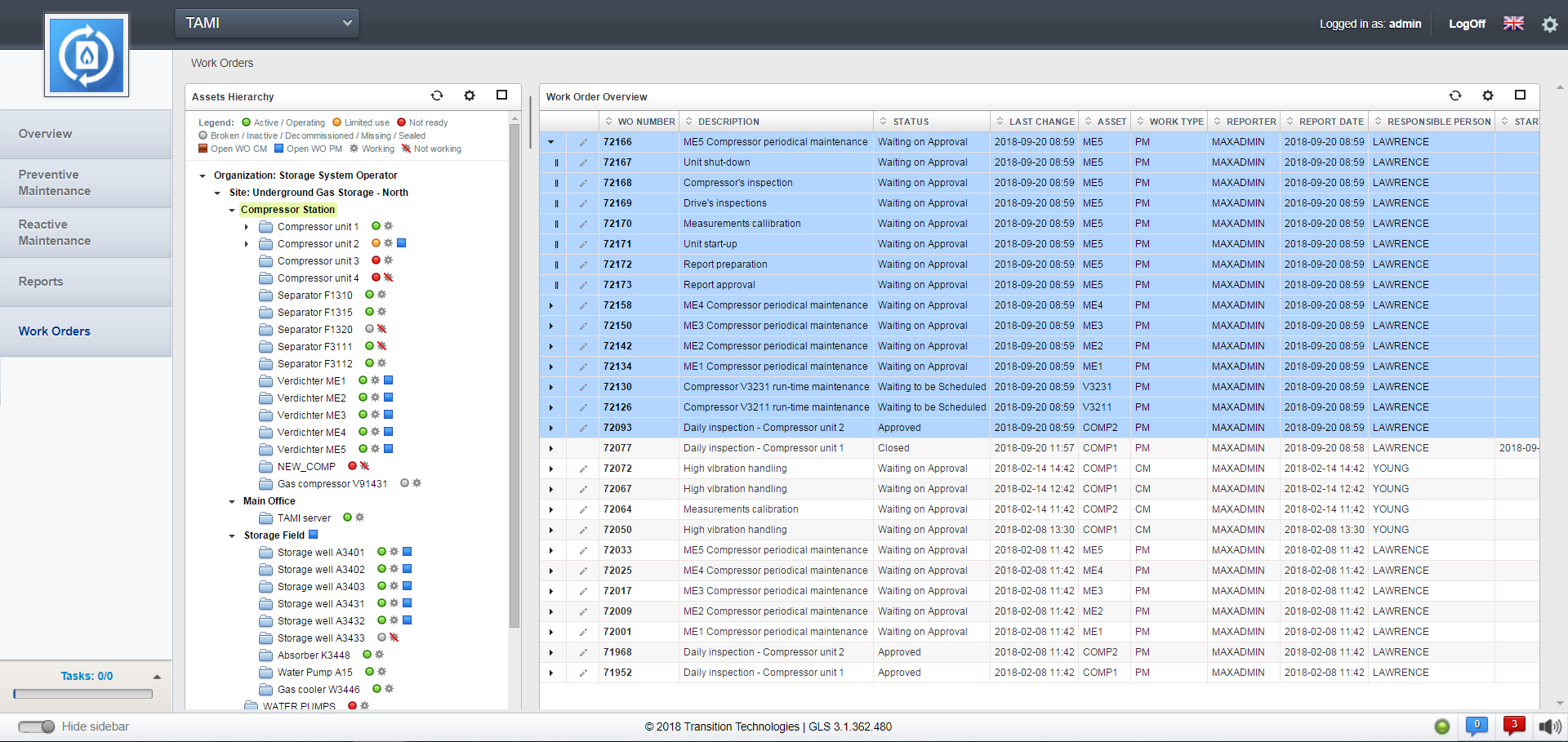

TAMI is a modern, fully featured solution for monitoring and management of technical assets. Its uniqueness consists in utilizing on-line, operational data for the real-time assets monitoring and maintenance workflows automation. TAMI’s role is creating a bridge between process data and technical assets. With the integration of user interface into that consistent information environment, there is a common space for all 3 areas.

The implementation of TAMI and its modules enables higher Return on Assets (ROA), contributes to increasing the site’s productivity and efficiency. Costs of Maintenance, Repairs and Operations can be reduced by 10-25 %.

Key functions

Manages assets and their corresponding specifications, safety plans, locations, structure, current conditions and operational status

Defines work orders with assigned workforce, tasks, safety plans, required parts and tools

Manages current and minimum inventory levels, allows automatic material orders and reserves materials for particular tasks

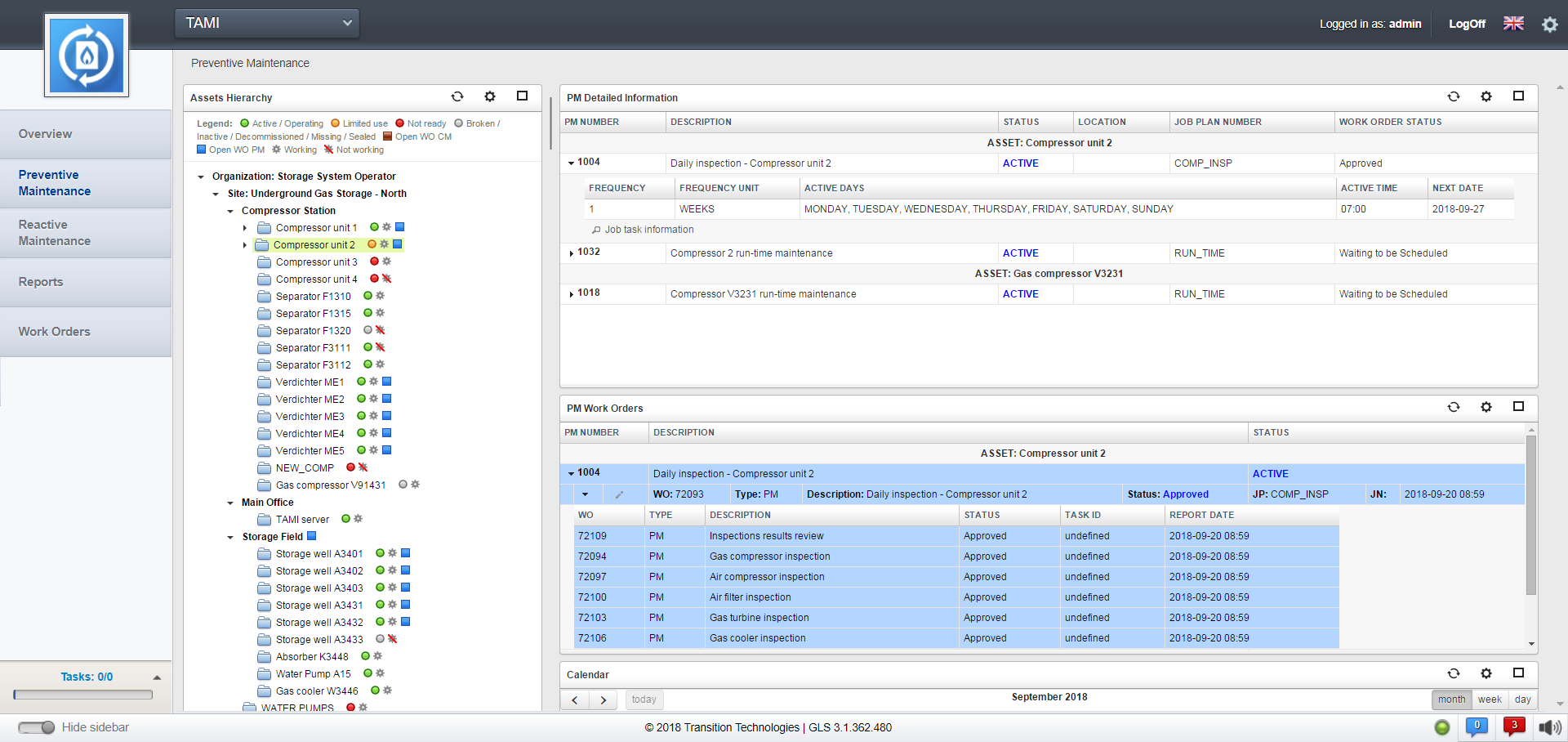

Allows planning of scheduled inspections and maintenance tasks and monitoring their further execution

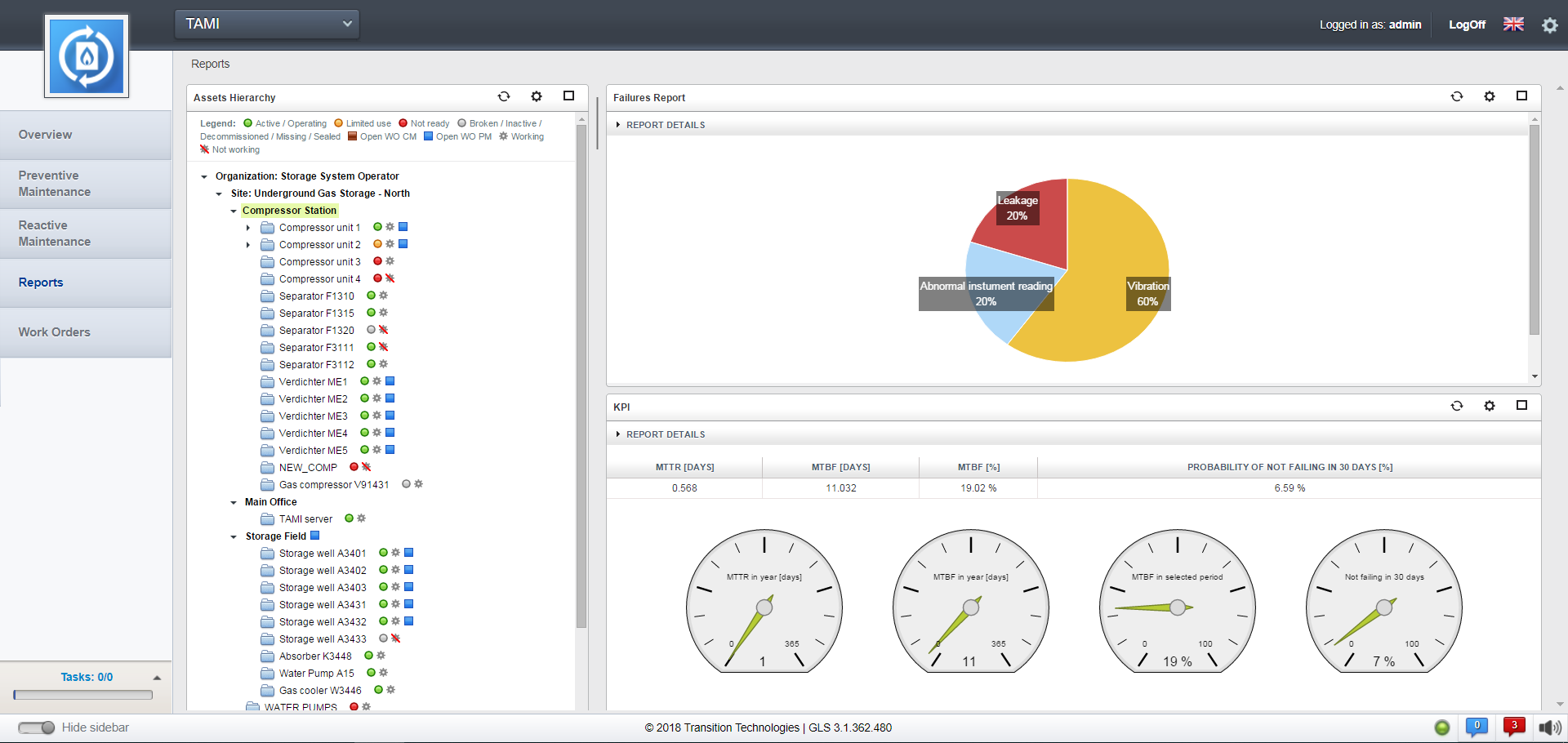

Dynamically acquires and displays data in fully customizable reports

Monitors system and network hardware by interfacing industrial process-side IT components